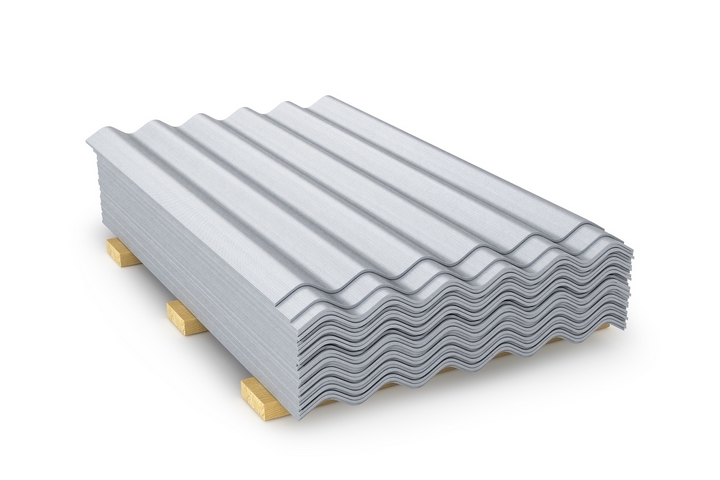

If you just walk or ride around your city, you will surely be able to see many examples of sheet metal ornaments. Metal roof shingles, metal statues, sheet metal cornices and other decorative elements are all around us. But have you ever wondered how these elements were created?

The 9 tools in this list can be used for sheet metal fabrication.

1. Shears

Sheet metal workers can use shears to cut through the metal sheets they will transform into beautiful and timeless decorative elements. These shears can be manual, hydraulic, or pneumatic, depending on the project being worked on.

2. Band saws

Band saws have special blades that are hard enough to evenly cut through metal sheets. Different types of bandsaws are available, and they can either be manual, semi-automatic or fully automatic. They can be horizontal, fixed, or mounted on a swivel.

3. Chop saws

Chop saws can also be used to cut metal sheets for sheet metal fabrication. Instead of regular blades, the chop saws that are destined to cut through metal sheets have an abrasive disc that make their job a lot faster and efficient.

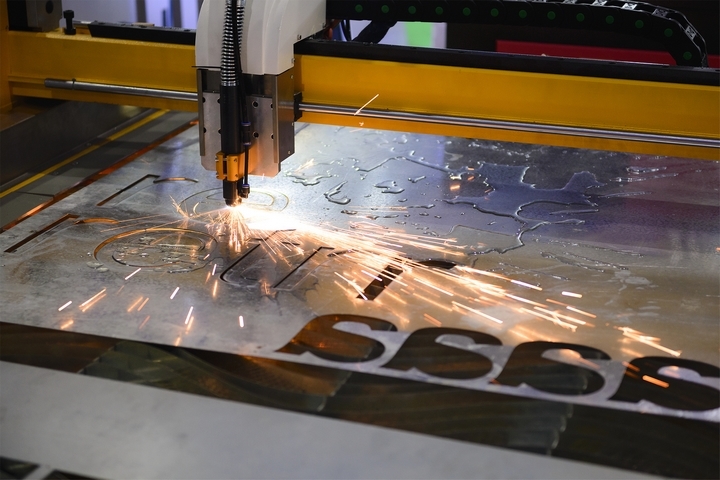

4. Cutting torches

When a sheet metal fabrication expert needs to cut large sections of sheet metal, they can use a cutting torch instead of a saw. Cutting torches don’t require a lot of efforts and make it possible to achieve great cuts.

5. Punches

Punching equipment is used to punch holes through metal sheets, so they can be assembled together with screws, or bolts and rivets. Punches can be manually operated, or can be part of a large machine that can punch and cut metal.

6. Rotary machines

Rotary machines are versatile since they can be used for crimping, beading, edging, burring, wiring, and flattening sheet metal. So much can be done with this type of equipment, and it can be useful for different sheet metal fabrication projects.

7. Hydraulic brakes

When sheet metal needs to be bended at determined angles, hydraulic brakes can be used. These machines make it easy to bend metal sheets with great precision, and they can be a part of many sheet metal projects.

8. Spotwelders

After sheet metal is formed, the different pieces need to be assembled together. For this purpose, sheet metal workers can use spotwelders. Different types of spot welders and different welding techniques can be used to ensure each sheet metal ornament is flawless.

9. Hammers

Hammers and other hand and power tools are also used to assemble the different pieces of a sheet metal ornament, and to help with the finishing touches. Sheet metal fabrication experts are extremely skilled.

10. Sand blasters

Finally, sheet metal ornaments are usually sand blasted, primed and painted before they can be delivered to the customers. Sand blasting machines come in different shapes and sizes, and will truly help bring any decorative sheet metal element to life.